The ball mill crushes materials through the impact and grinding effect of the grinding media. In this process, the steel ball is used a medium of energy to transform ...

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size ...

Ball mill A typical type of ... However, the smaller the rods, the larger is the total surface area and hence, the greater the grinding efficiency. Autogenous mill

The energy efficiency of ball milling ... dry ball milling efficiency was found to be ... if it is compared with that of a ball mill operating under the ...

Closedcircuit systems. The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills ...

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling ... LOW TEMPERATURE – Because of the high efficiency of milling and low heat ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery

Addition of pebbles to a ballmill to improve grinding efficiency. ... Ballmills are used widely for ... and the resultant excess of pulp may affect the efficiency ...

A ball mill generally loses its grinding efficiency remarkably at fine grinding. This is because fine particles from ground materials agglomerate and adhere to the ...

ball mill grinding efficiency YouTube. Feb 13, 2016, Contact Us For Help: wwastonecrushersolutionorg/solutions/solutions 2012 High Efficiency Cement Ball Mill ...

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

FLSmidth ball mill for cement grinding. ... absorption and grinding efficiency. For special applications a classifying shell lining may be supplied for fine grinding

Steel Ball Mills. Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into ...

Improving The Efficiency Of Fine Grinding ... efficiency of stirred mills compared to ball mills is ... Efficiency Of Fine Grinding – Developments In ...

Ball mill critical speed, ball mill efficiency. What is the ball mill critical speed and how to improve ball mill efficiency ? Read More...

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed ...

FLSmidth ball mill for cement grinding. Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or ...

ball mill efficiency factor. making your own porcelain ball mill jars With the PVC ones I would wonder if you would lose milling efficiency by having the smooth ...

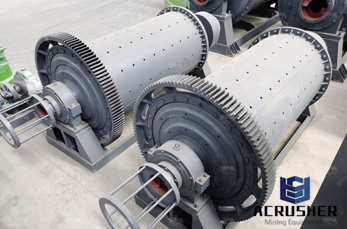

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

High efficiency grinding slag ore ball mill,View ball mill . High efficiency grinding slag ore ball millOn this Product Details Page, You Can Find Comprehensive ...

Ball mill is the key equipment for crushing the material after it is broken. Ball mill is one of the high fine grinding machines widely used in industrial production ...

To achieve a reasonable efficiency with ball mills, ... This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between ...

ball mill feed has been ... The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of ...

WhatsApp)

WhatsApp)