Milling and Machining Center Basics Fundamental Manufacturing Processes Video Series Study Guide 3 In all kinds of milling a critical component is the workholding ...

Hard turning is a highly costeffective process (compared to grinding) and is often used in combination with grinding operations.

Traditional vs. nontraditional processes Ultrasonic machining ... Surface grinding is an abrasive machining process in which the grinding wheel removes material from

Union Process provides Toll Milling and Toll Grinding services for customers who wish to save on the cost of capital equipment, personnel, space required and other ...

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A wide variety of machines are used for grinding: Handcranked knife ...

,grinding,grinding,grinding,grinding,grinding,grinding。

A grinding machine is not a machining center, but it can sometimes take on milling and drilling (or even turning) to make the overall process more efficient.

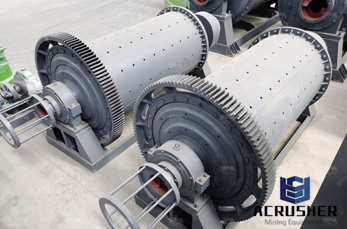

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process .

Milling Grinding Process, Wholesale Various High Quality Milling Grinding Process Products from Global Milling Grinding Process Suppliers and Milling Grinding Process ...

Prater provides toll milling and toll grinding for companies in need of toll processing and toll manufacturing services.

Milling may refer to: Milling (grinding), the process of grinding grain or other materials in a mill; Milling (machining), the process of machining metal via non ...

Milling and Grinding Ball mills: ... tungsten carbide or PTFE. You are able to ensure an outstanding grinding process and avoid contamination of your sample.

Machining Operations. ... Precision grinding as often used as a finish machining process. Precision grinding ... A vertical milling machine ...

Effective grinding and milling of metal ores is essential in liberating and recovering valuable minerals. Energy consumed in the comminution process is a major cost ...

Chapter 18. Feed Milling Processes. 1. INTRODUCTION 2. ... Grinding or particlesize reduction is a major ... It is not used as a final process for reducing the size ...

Study of precision milling and grinding process technology for aspheric components on ResearchGate, the professional network for scientists.

Throughout the entire process our stringent quality control procedures will ensure your toll blending, milling and grinding requirements are met safely and consistently.

Ultrasonic WetMilling and MicroGrinding. Ultrasonication is an efficient means for the wetmilling and microgrinding of particles. Besides dispersing and ...

Gold Ore Grinding Mill for Milling Process. In applying MPC algorithm to ball mill grinding process, such as the, it is necessary to properly select the values of ...

Milling Grinding Flaking Buhler Group. Milling Grinding Flaking Every detail counts. The roller mill is by far the most important grinding machine in a mill.

Expanding capacity matters to grinding and milling ... you need to go to in order to ensure that every step of the machining process is as efficient and ...

A sixweek course designed to take students through the complete cycle of raw material grinding and preparation, clinker grinding, milling and separation cycles.

Raleigh Paving offers commercial asphalt milling grinding, and our detailed process saves you time and money. Request a free quote today!

WhatsApp)

WhatsApp)